Chronicle

PJ Harvey helped reshape the sound and aesthetic of alternative music with fearless artistry and emotional precision. This feature explores how her raw, poetic energy continues to influence musicians and designers alike.

- December 10, 2025

More than a genre, Indie music has always been a declaration of creative freedom. Its sound and style have shaped how we define authenticity. This Vinylize story celebrates the movement’s fearless individuality and the frames that echo its ethos.

- December 01, 2025

From Bowden’s 1896 brake cable to today’s carbon fibre frames, cycling’s story and evolution is one of materials. Steel, aluminium, and carbon have each redefined not only how bikes ride, but also who rides them and why.

- November 20, 2025

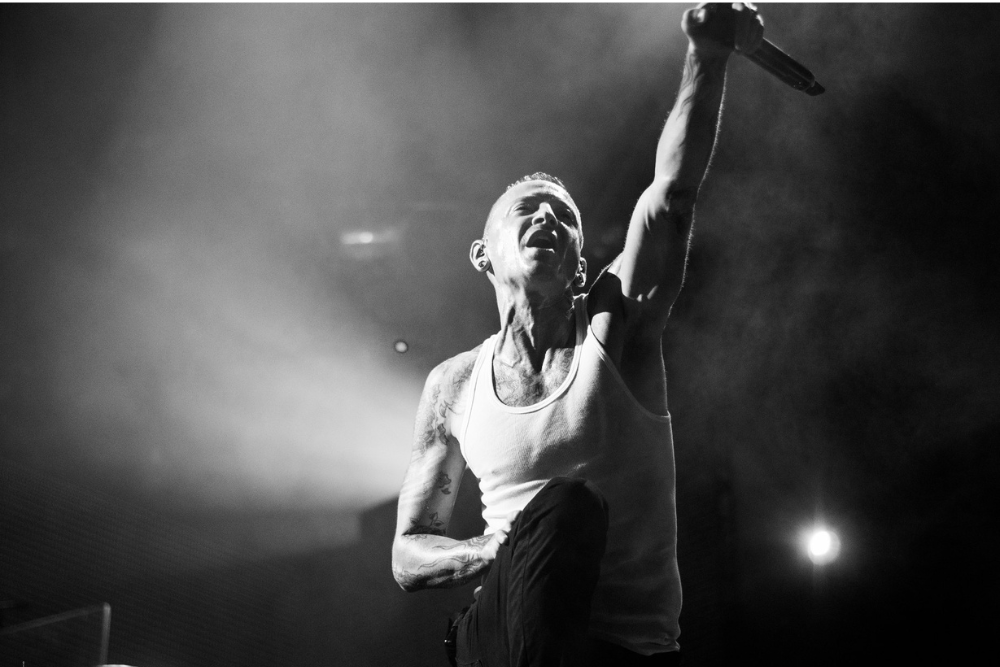

Chester Bennington’s raw, urgent voice defined a generation, with the frontman bridging rock and vulnerability in a way few artists could. This Vinylize tribute examines how his sound revolutionised modern rock and how the Chester optical frame embodies that same balance of power and precision.

- October 31, 2025

From fronting a Judas Priest tribute band to stepping into Rob Halford’s shoes, Tim “Ripper” Owens’ journey is the stuff of heavy metal legend. His fierce, operatic voice and uncompromising stage presence echo the bold lines of the Ripper optical frames: sharp, defiant, and built for those who live loud.

- October 04, 2025

A new series exploring the vinyl stylus and how this small yet vital component has helped shape the way we listen and connect with music. Part 1 traces its journey from early recorded sound to a crafted, finessed, and in some cases, hand-built artisanal tool.

- September 30, 2025

Eyewear shapes how the world perceives us, and how we perceive it in return. Framed: Eyewear Through Style and Time is a new series that unpacks the juxtaposition of utility and identity, designs and cultural memory. We begin with Part 1, and a design of inevitability: Classic round frames.

- September 23, 2025